About Ecofab Delivering Solutions Together

Our history is who we are

Since 1975, we’ve believed in innovation and partnering with our customers to create unique solutions. Every step of the way, we’ve committed to the motto that “service always comes first,” and our approach has seen Ecofab go from a Canadian solution to a global one, where we create custom railcar covers to meet customer requirements and help businesses adhere to environmental regulations and industry demands.

Today, we offer comprehensive railcar cover leasing options and tailored solutions for our customers around the world. Every journey is unique, and together, we can create a solution for any railcar cover project.

Our Company History

1975

Founded in 1975, Ecofab develops one-piece fiberglass covers for gondola railcars, solving an industry-wide materials handling issue. The concept of a reusable railcar cover revolutionized the industry and stopped dust losses, leading to the birth of Ecofab.

1990

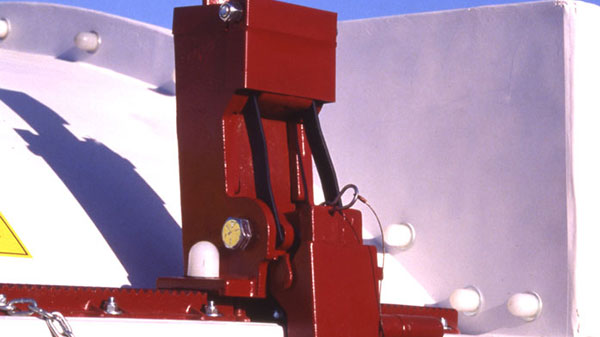

Implementing an automatic locking mechanism, we redesigned our initial railcar cover so each cover could be completely removed and replaced via a forklift with no manual labour required. This development further enhanced user safety and reduced the time to remove or replace a railcar cover.

1994

Expanding operations to the United States, the Ecofab team began working to cover contaminated soils. These operations involved gaining regulatory approvals for protecting low-level radioactive material in transit.

1996

Entering South America, Ecofab began distributing railcar covers to a major Argentinian mining operation. This was a big year for us, as we also started operations in Broken Hill, Australia. The commencement of these operations demonstrated the environmental benefits of Ecofab railcar covers to the industry and to the community.

1999

Testing our ability to customize solutions, our team developed a unique solution utilizing ex-coal hopper railcars. An Australian railroad had a need for replacement grain hoppers, so Ecofab designed a semi-automatic railcar cover that could be attached to ex-coal hopper railcars. The covers overcame the need to spend capital on new Rollingstock, and safety incidents were greatly reduced because no staff were required to access the top of railcars during loading.

2000

Ecofab introduces fully automated railcar covers to the Australian market, enabling automatic, continuous loading of trains fitted with new Ecofab covers. Additionally, to improve operations and logistics, our team gains ISO quality assurance accreditation.

2013

Chile becomes the next country in South America to adopt Ecofab railcar covers. Our fiberglass railcar covers meet the stringent environmental requirements for mining operations and provide enhanced materials handling, especially during the wet season.

2015

Coal ash becomes an environmentally sensitive material, and large-scale relocation projects begin in the United States. These projects required gondola railcars to be completely covered to eliminate spillage and dusting of coal ash, making Ecofab an integral part of the industry.

2017

Ecofab releases a new pneumatically operated railcar cover in Australia, which challenged our team to design a cover that could fit within a very restrictive space and remain within the clearance profile. We also implemented new technology to our fiberglass production line that enabled faster production with enhanced quality.

2020

Ecofab unveils the AutoHatch, an innovation in automated hatch systems for hopper railcars in North America. This ground-breaking product has required our team to overcome the significant challenge of designing an all-weather hatch system that can be operated from ground level, significantly reducing the risks associated with manual hatch operation. The AutoHatch is a testament to our commitment to safety, efficiency, and quality.